Aluminum, a versatile and widely-used metal, has become an integral part of our daily lives, from transportation to packaging. But have you ever wondered where aluminum comes from? Understanding the source of aluminum is crucial not only for those in the industry but also for consumers who are increasingly concerned about sustainable practices and environmental impact. In this article, we will explore the origins of aluminum, its extraction process, and its significance in various applications.

Aluminum is the third most abundant element in the Earth's crust, making up about 8% of its weight. Despite its abundance, the process of extracting aluminum from its ore is complex and energy-intensive. This article delves into the journey of aluminum from bauxite mining to the final product, offering insights into the economic and environmental considerations involved in its production.

By understanding where aluminum comes from and how it is produced, we can better appreciate its role in our lives and make informed decisions about its use. Let's dive deeper into the fascinating world of aluminum and uncover the processes that bring this essential metal to our homes and industries.

Table of Contents

- 1. What is Aluminum?

- 2. The Origins of Aluminum

- 3. The Bauxite Mining Process

- 4. The Bayer Process: Refining Bauxite into Alumina

- 5. The Hall-Héroult Process: Producing Aluminum

- 6. Environmental Impact of Aluminum Production

- 7. Applications of Aluminum

- 8. The Future of Aluminum Production

1. What is Aluminum?

Aluminum is a lightweight, silvery-white metal known for its excellent corrosion resistance, high thermal and electrical conductivity, and malleability. It is non-toxic and can be recycled indefinitely without losing its properties, making it a sustainable choice for various applications. Aluminum is used extensively in industries such as automotive, aerospace, construction, and packaging, contributing to its global demand.

2. The Origins of Aluminum

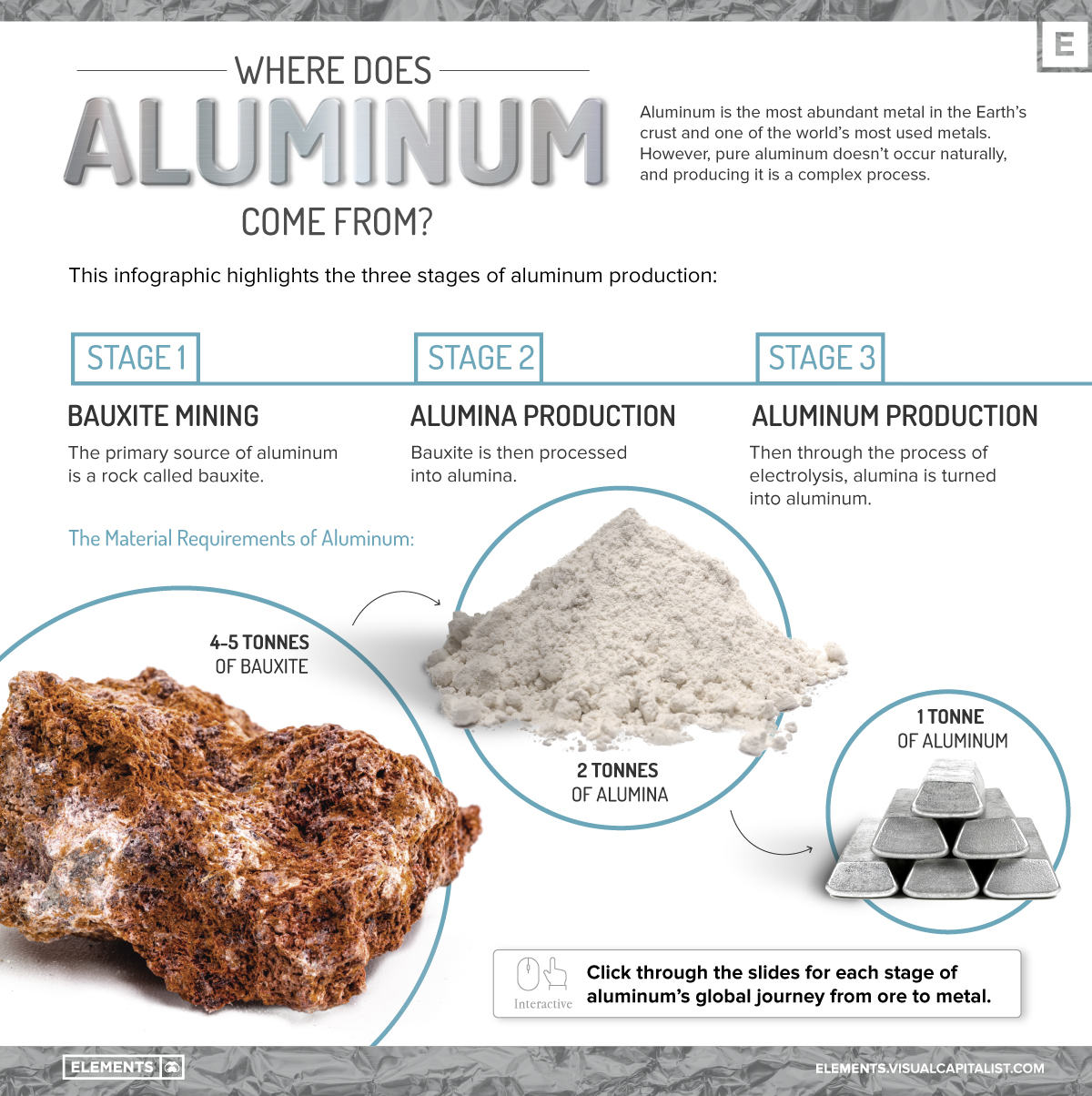

Aluminum was first discovered in the early 19th century, but its commercial production did not begin until the late 1800s. The primary source of aluminum is bauxite, an ore that contains a high percentage of aluminum oxide (Al2O3). Bauxite is typically found in tropical and subtropical regions, where weathering processes have concentrated the aluminum-bearing minerals.

Key facts about aluminum's origins:

- Aluminum was first isolated in 1825 by Danish chemist Hans Christian Ørsted.

- The name "aluminum" is derived from the Latin word "alumen," meaning bitter salt.

- Commercial production began in 1888 with the establishment of the first aluminum smelting plant.

3. The Bauxite Mining Process

The journey of aluminum starts with the extraction of bauxite from the earth. Bauxite deposits are typically found close to the surface, making them relatively easy to mine. The mining process usually involves the following steps:

- Site preparation: Clearing vegetation and soil to access the bauxite ore.

- Drilling and blasting: Extracting bauxite from the rock using explosives.

- Transport: Moving the mined bauxite to processing facilities.

3.1 Global Bauxite Production

As of recent data, the top producers of bauxite include:

- Australia

- China

- Brazil

- India

These countries contribute significantly to the global supply of bauxite, which is essential for aluminum production.

4. The Bayer Process: Refining Bauxite into Alumina

Once bauxite is mined, it undergoes the Bayer process, developed by Karl Bayer in 1887. This chemical process refines bauxite into alumina (aluminum oxide) through the following steps:

- Crushing and grinding the bauxite into a fine powder.

- Mixing the powder with sodium hydroxide and heating it under pressure.

- Separating the undissolved impurities from the aluminum-bearing solution.

- Precipitating aluminum hydroxide from the solution by cooling and seeding.

- Calcining the aluminum hydroxide at high temperatures to produce alumina.

5. The Hall-Héroult Process: Producing Aluminum

The final step in aluminum production is the Hall-Héroult process, which involves the electrolysis of alumina to produce aluminum metal. This process requires significant energy, as it operates at high temperatures and uses a large amount of electricity. The key steps include:

- Dissolving alumina in molten cryolite to lower its melting point.

- Passing an electric current through the solution to reduce aluminum ions to metal.

- Collecting the molten aluminum at the bottom of the electrolytic cell.

The Hall-Héroult process is responsible for over 90% of the world's aluminum production.

6. Environmental Impact of Aluminum Production

While aluminum is a highly recyclable material, its production process has significant environmental impacts. The extraction and refining of bauxite, as well as the energy-intensive electrolysis process, contribute to greenhouse gas emissions and other environmental concerns. Key issues include:

- Deforestation and habitat destruction from mining activities.

- Water pollution from the discharge of red mud, a byproduct of the Bayer process.

- High energy consumption leading to increased carbon emissions.

Efforts are being made to mitigate these impacts through sustainable practices and the development of more efficient production technologies.

7. Applications of Aluminum

Aluminum's unique properties make it suitable for various applications across multiple industries, including:

- Aerospace: Lightweight components that enhance fuel efficiency.

- Automotive: Use in vehicle frames and body panels to reduce weight.

- Construction: Windows, doors, and roofing materials that offer durability and aesthetics.

- Packaging: Aluminum cans and foils that preserve food and beverages.

These applications highlight the metal's versatility and importance in modern society.

8. The Future of Aluminum Production

The future of aluminum production is likely to focus on sustainability and innovation. As demand for aluminum continues to grow, so does the need for more environmentally friendly production methods. Potential developments include:

- Increased recycling rates to reduce the need for primary aluminum production.

- Investment in renewable energy sources to power aluminum smelting operations.

- Research into alternative production methods that minimize carbon emissions.

By embracing sustainable practices, the aluminum industry can reduce its environmental footprint while meeting the needs of consumers.

Conclusion

In conclusion, understanding where aluminum comes from and the processes involved in its production is essential for appreciating its role in our lives. From the mining of bauxite to the refining and smelting processes, each step has implications for the environment and economy. As consumers, we can advocate for sustainable practices and support industries that prioritize eco-friendly production methods.

We encourage you to share your thoughts on aluminum production in the comments below and explore more articles on related topics to deepen your understanding of this vital metal.

Closing Remarks

Thank you for taking the time to learn about aluminum and its origins. We hope this article has provided valuable insights and encourages you to return for more informative content in the future.

What Episode Does Jimmy Leave Yellowstone? An In-Depth Analysis

Tonight's Northern Lights: A Spectacular Natural Phenomenon

Average Height For Men In America: Understanding The Trends And Implications